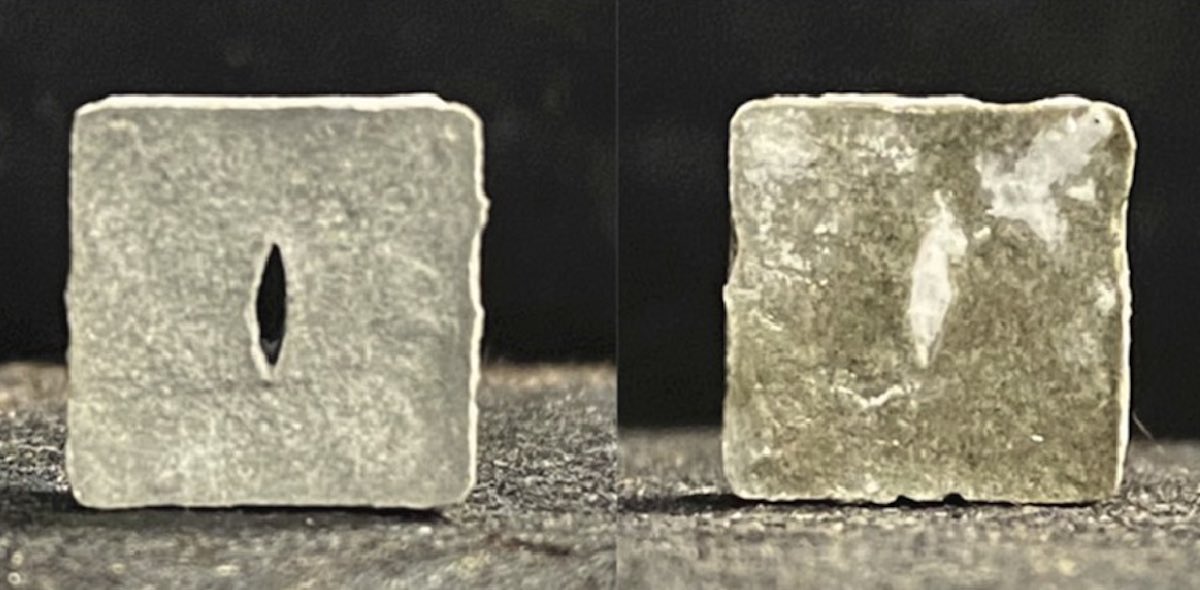

Self-healing Concrete is an amazing invention in the building construction industry. Its use can help to keep things from deteriorating before they reach the end of their useful lives. Concrete is still one of the most widely used building materials, from foundations to structures such as bridges, dams, retaining walls, and underground parking lots. When exposed to tension, traditional concrete has a flaw: it cracks. (1)

In this new concrete, the material begins to fill in the crack gap itself.

Since 2006, the Civil Engineering and Geosciences Faculty in Delft has been working on self-healing concrete, which is made by mixing a healing agent or bacteria into the concrete to convert nutrients into limestone.

This study looks at the self-healing properties of plastics, polymers, composites, asphalt, metals, and concrete from a broader perspective.

A Dutch scientist, Hendrik Jonkers, was the first to create self-healing concrete, a product that, despite its higher initial cost, could save money and time in the long run. For his invention, Hendrik Jonkers has been nominated for the European Inventor Award of 2015. (1)

The Need for Self-healing Concrete in the Current Era

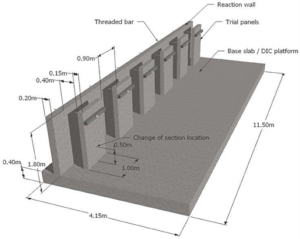

Since its invention, concrete has remained one of the most important construction materials, and it will continue to be so in the future, but most concrete structures are prone to cracking.

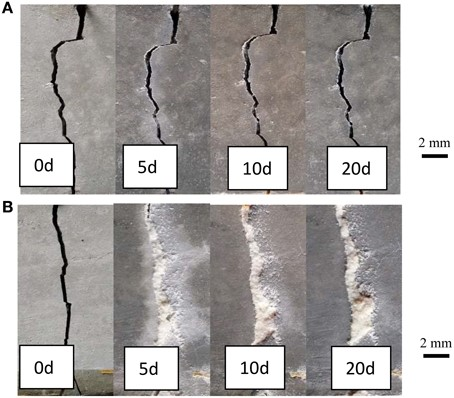

Even a small crack in the concrete surface exposes the entire structure to deterioration because water seeps in and degrades the concrete and corrodes the steel reinforcement, drastically reducing the structure’s lifespan. (2)

Concrete is good at resisting compressive force but not so good at resisting tensile force.

Steel reinforcement is used in concrete for this reason. Excessive tensile force can cause cracks in many concrete structures, and these can happen quickly after the structure is built. A concrete mortar that is bonded to the damaged surface is used to repair this crack.

To ensure that the crack mortar does not fall away, it is sometimes necessary to insert metal pins into the existing structure. Any concrete repair or maintenance takes longer, and it’s often difficult to gain access to the structure to make repairs, especially if it’s underground or at a great height. (2)

The working of the self-healing Concrete

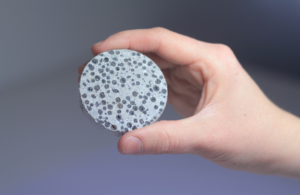

Self-healing concrete is a type of concrete that contains healing bacteria that produce limestone biologically to heal cracks that appear on the surface of concrete structures.

Only a few types of bacteria, such as the Bacillus genus, can produce healing limestone, which is mixed with concrete ingredients along with a calcium-based nutrient known as calcium lactate, as well as nitrogen and phosphorus. These specific bacteria can survive for more than 200 years in concrete. (3)

The Bacteria For Self-Healing Concrete

Finding the right bacteria capable of surviving in an extremely alkaline environment is essential for making self-healing concrete. As we all know, mixing water and cement produces a pH of up to 13, which is usually a hostile environment for life.

At a pH of more than 10, the majority of microorganisms will die. Microbes that thrive in alkaline environments, such as carbonate-rich soils in desert areas of Spain, soda lakes in Egypt, and alkali lakes in Russia, are required to make concrete with self-cracking properties. (3)

Self-healing Concrete: Advantages

- Self-healing concrete can repair itself without the need for additional treatment.

- It has higher compressive and flexural strength than regular concrete.

- It has a high level of resistance to freeze-thaw attacks.

- The permeability of self-healing concrete is low.

- Reduce steel corrosion by reducing crack self-repair, which is a major cause of corrosion.

- The bacteria used in self-healing concrete, such as Bacillus bacteria, are harmless to human life and thus can be used effectively. (3)

Self-healing Concrete: Advantages

- Self-healing concrete is nearly twice as expensive as regular concrete.

- Different environmental conditions can affect the growth of bacteria.

- Clay pallets mixed in concrete cover nearly 20% of the volume of the concrete, which could cause a shear zone or fault zone in the concrete. (3)

References:

- https://www.intechopen.com/chapters/72141

- https://www.buildersmart.in/blogs/self-healing-concrete

- https://www.lorman.com/resources/what-is-self-healing-concrete-17376

- Main image:https://www.goodnewsnetwork.org/self-healing-repairing-concrete-pulls-co2-out-of-the-air/