Digital tools have a wide range of uses and effects in the built environment. In this collection, we’ll look at projects in which technology had a significant part in the design of each of the project’s aspects, as well as the ultimate construction and outcome. These prototypes are also the result of extensive study to reduce the time, cost, and waste associated with traditional construction methods.

Digital fabrication, robotics, augmented reality fabrication interfaces, 3D printing and scanning, and a variety of software is used to optimize processes while also maintaining certain craftsmanship, design elements, and aesthetics for high-quality architectural spaces, while also allowing architects and designers to intervene throughout the process.

Despite the epidemic, an unprecedented number of creative 3D-printed buildings were built in 2021, including Cucinella’s house and others in the Netherlands, Denmark, the United States, and Dubai. (1)

Key advantages and disadvantages of 3D printed buildings

The capacity to build complex forms, a significant decrease in construction time and costs and replicability are the key advantages of 3D printing over traditional construction processes.

The primary drawbacks are a restricted selection of construction materials (now, largely plain concrete) and a lack of data on durability and weather resistance. (1)

The construction technique involved

Several 3D printed houses were constructed utilizing a technology in which a 3D printer deposits hundreds of layers of fluid concrete to build hollow walls. A gantry crane or a robotic arm can be used to support the printer nozzle.

The concrete mix must be fluid enough for the nozzle to readily extrude it, but not so much that the walls, which do not require any formwork, become unstable until the concrete hardens. Insulation is installed in the wall cavity as soon as the concrete is suitably hardened, and tubes and wires are installed in previously printed technical ducts.

The printer can also manufacture interior items such as stoves, bathrooms, and bathtubs while producing the walls. A whole detached house might take anywhere from 24 hours to a week to print. (2)

Prefabrication should start to lead the construction industry

The current issues that have sparked the development of 3D printing on a large scale have a clear goal: to speed up and simplify construction processes. This looks to be the greatest current problem, and prefabrication appears to be an effective and logical path to take in conjunction with these new technologies.

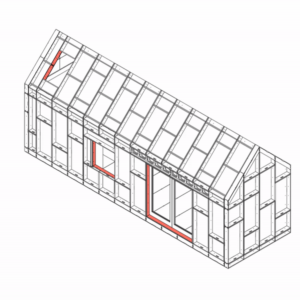

Field operations are generally focused on the assembly of pre-engineered and mass-produced components and systems that are moved from a factory to their ultimate site. Although there have been significant approaches to prefabrication since the 16th century, it is now poised to overtake traditional on-site production processes in the building sector. (2)

Prefabrication and 3D printed architecture as the future

Prefabrication not only speeds up the process, but also allows for “building without builders,” lowering the overall complexity and resulting in material, monetary, and energy savings.

Some architects, such as those from SUMMARY in Portugal, even go so far as to say that traditional building is bound to fail: “With population expansion, there are more and more people who require houses to live in, and less and fewer people are skilled or available to build them.”

Prefabrication will be the sole solution as an industrialized approach, and it will gradually become the exception to the norm.” Prefab housing might make construction and homeownership cheaper, but good architectural design should not be sacrificed. (3)

3D printed and Prefabrication; lookout toward future

Prefabrication, in effect, produces a paradigm shift that changes the way we think about projects from the start. Building efficiency can now be the beginning point, compelling us to first comprehend construction processes before designing the space’s shape and functionality.

Only methods are reversed, not design quality. This is evident in the vast number of similar projects that are posted on our site every day. (3)

It is obvious that technology has infiltrated practically every facet of our life. It has influenced the way we interact, connect, work, and learn, as well as our purchasing and eating habits. Technology is now present in the way architecture and construction are considered, created, and produced, and it was not an exception. (3)

REFERENCES :

- https://metropolismag.com/viewpoints/3d-printing-is-speeding-up-the-automation-of-construction/

- https://www.inexhibit.com/case-studies/3d-printing-in-construction-where-are-we-now/

- https://www.archdaily.com/973281/3d-printing-prefabrication-and-interior-design-construction-trends-for-2022